CFD Modeling

INTRODUCTION

Developing microscale medical diagnostic devices presents unique challenges. With macroscopic devices, such as conventional blood chemistry analyzers or flow cytometers, it is usually possible during the development phase to mount flow sensors, temperature probes, and optical detectors at various positions along the instrument pathway to experimentally determine the optimum operational parameters for the device. However, this approach usually fails for microdevices as standard sensors and probes are typically of the same scale as the microdevice. These relatively large sensors interfere so much with the experiments that any results generated do not represent the actual performance of the system. Sensors or detectors that are two, or more, orders-of-magnitude smaller, as is the case for macro-scale devices, do not generally exist. Thus, the only valuable experimental data tend to be external measurements and the internal physics of the microdevice is left to conjecture. Fortunately, modeling of microscale processes provides a uniquely useful tool to develop microanalytical devices and optimize their operational parameters, since the chemical and physical processes in the microscale generally follow deterministic physical laws that can be accurately represented in mathematical models. One example is micro-scale fluid flow, such as any physiological fluid through capillary-sized channels, is devoid of the chaotic nature of turbulence, and thus can be accurately and deterministically represented by a mathematical model. A second example is precise control of chemical reaction rate by designing the diffusive mixing of the reactants. Modeling can also greatly enhance the interpretation of experimental results, both during the device development phase and later during development of the measurement algorithm for device operation. When utilized in tandem with modeling, experimentation can accurately measure global behavior and validate the model, while modeling can predict internal behavior at any point in space and time in the microdevice, leading to new insights, understanding, and optimization techniques, e.g., the accurate fitting of non-linear response functions, optimization of system dynamics, or location of a specific region of incomplete reagent mixing, complete with design modifications that will remedy the problem.

Diffusion, Flow, and Chemical Reaction Modeling

Mathematical modelling and analyses contribute to the design of the most important aspects of the design of a fluid-based system. Here is a partial list of analyses and some of the results obtainable.

Pressure-Driven Flow Analysis

- fluid velocities and pressures

- flow of multiple liquid streams with different viscosities

- viscosity change with diffusion

- pressure forces due to surface tension

- cavitation pressure limit

Starting Flow, Stopping Flow Analysis

- dynamic response of liquids and gases in a network of channels to changes in applied pressure

- locations and amplitudes of unanticipated backflows

- response times to steady flow

Mixing Analysis

- comparison of diffusive mixing to convective mixing

- optimization of mixer designs

Multicomponent Diffusion Analysis

- molecular and convective diffusion rates and extent of specified molecular species in a particular geometry

- linearized Stefan-Maxwell methods to model interactions of multiple components

Surface Binding & Chemical Reaction Analysis

- diffusion with rate-controlled or mixing-controlled chemical reactions

- surface binding with given site density and adsorption/desorption rates

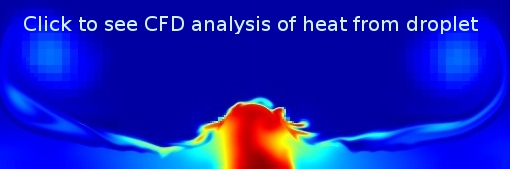

Heating/Cooling & Evaporation/Condensation Analysis

- transient heat transfer and thermal response time

- mass transfer

- combined heat & mass transfer - Stefan flow

Particle Suspensions Analysis

- particle motion in sprays and channels

- settling velocity & sedimentation

- enhancement or limitation of viscous resuspension